Reduce your electricity bill

The experience with already installed FORCE systems is savings up to 15%.

The savings depend on the load on the installation and the types of components the system is connected to. The standard savings are around 7-15%.

The system works with all types of installations, such as industrial, office, private, pumps and fans.

The greatest savings are achieved on high-load installations.

The advantages of the system are a lower electricity bill, reduced CO2 emissions and lower operating costs.

The system improves:

- the electrical conductivity.

- the lifespan of connected electrical equipment and engines.

The system reduces:

- electricity consumption.

- harmonic distortion.

- high / low frequency noise.

- electrical resistance.

- equipment malfunction.

- CO2 emissions.

- operating costs.

Other benefits:

- Short payback time.

- Amplifies other power-saving measures.

- No polluting waste products post-use.

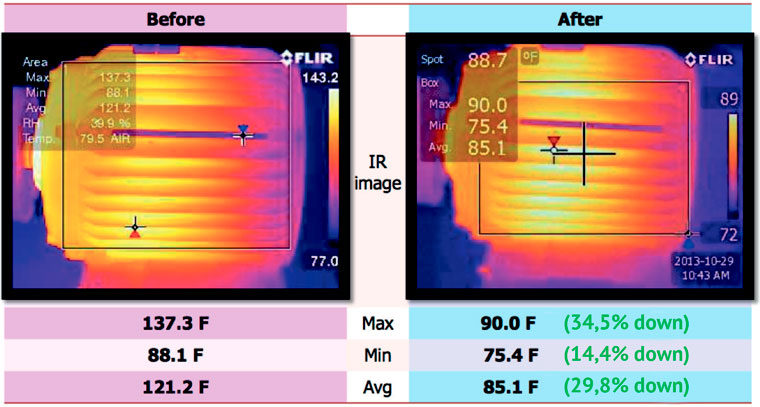

Harmonic distortion and heat dissipation are reduced by up to 30%

Hvacon manages the installation

HVACON is an experienced and licensed electrical installer and we have years of experience with energy optimization both on land and on ships.

HVACON offers a complete solution with documentation, delivery, installation and analysis.

We review the installation, prepare the documentation and measure and analyze the results.

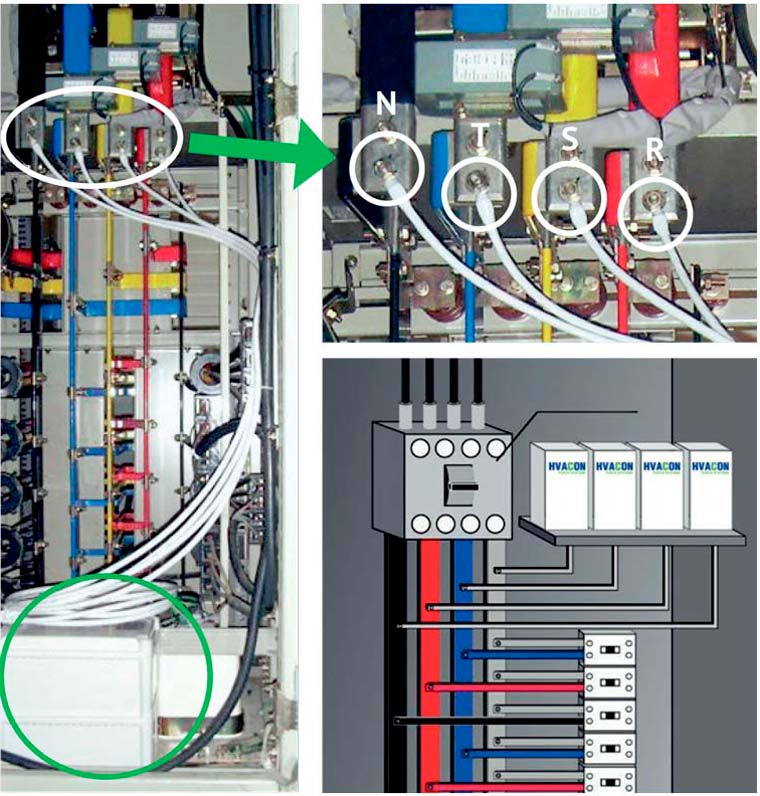

The FORCE boxes are installed either at/in the motherboard or beside the specific equipment.

The system is installed in parallel with the existing installations and it can be connected directly to the rails or switches/terminals without changing existing installations/terminations.

The system is available in all sizes and is easy to operate.

The system is completely maintenance-free, but we will gladly provide assistance with an analysis of the power measurements. We make everything easy for you.

Reduce your electricity consumption!

The HVACON Group is a well-known provider of HVAC, electrical and automation solutions for both marine and onshore applications.

The HVACON companies are Danish-owned with branches in several locations in Denmark and the United States. As a licensed electrical installer, we guarantee a safe and legal installation. We are an experienced company that is proud to deliver a fine product on time.

Our solutions ensure the greatest savings and the shortest payback time.

You are always welcome to contact us for a non-binding visit or offer.

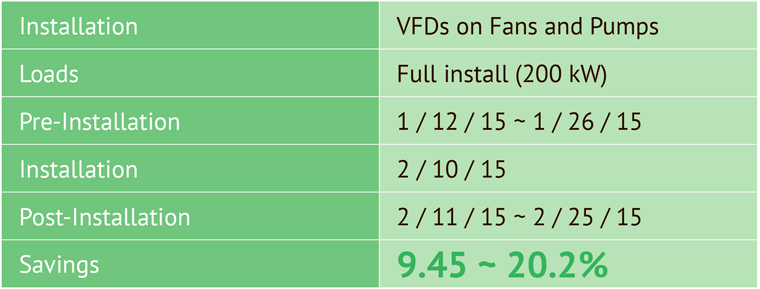

Measurements and Test results

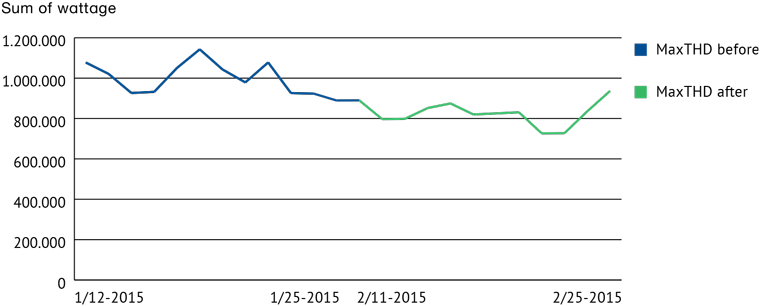

Below is a measuring example from an installation in Seymour, Wisconsin, USA. It shows the result of a fan and pump installation with frequency inverters. Both savings and THD are measured here.

Frequency converters are widely used in connection with fans, pumps and other engines, since frequency converters provide operational savings. The problem with frequency converters is that they can generate harmful harmonic interference.

Harmonic interference can affect the entire installation. It causes energy loss and increase energy consumption.

This measurement shows the harmonic interference of daily consumption with the same load before and after FORCE was installed. There is a visible reduction in the harmonic disturbances.

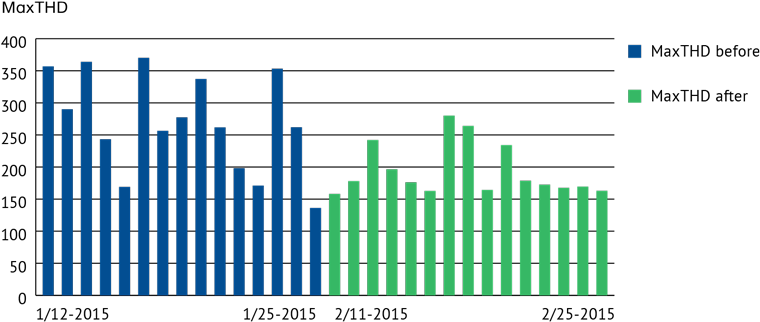

Max THD – before and after FORCE installation

The above graphs show maximum harmonic disturbance (HD) both before and after the installation of FORCE.

1. The above graphs show maximum harmonic interference (HD), both before and after the installation of FORCE. There is a clear reduction in the total maximum HD after the installation of FORCE.

2. No equipment can completely eliminate harmonic interference, but any reduction will result in both improved supply quality and lifespan of connected equipment.

3. After installing FORCE, the total maximum HD reduction was nearly 30%.

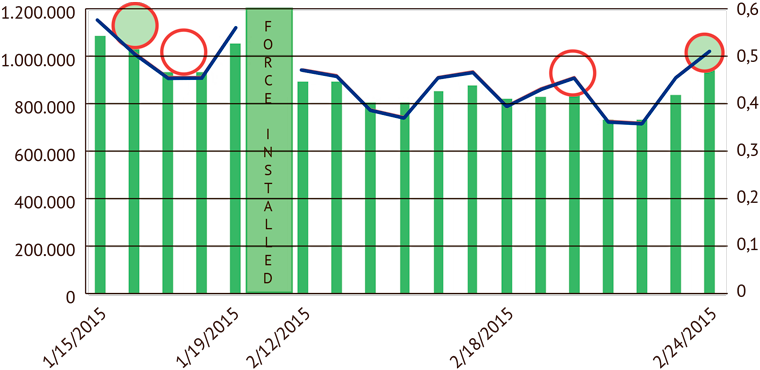

Average wattage consumption reduced by 20.2%

(Measured on all days and excluding new equipment)

1. The above graph shows the average daily effect/power consumption both before (blue graph) and after (green graph) the installation of FORCE.

2. A reduction in the average wattage consumption is, generally speaking, an indication of a reduction in total consumption (kW and kWh) if all consumers have the same flow and operating time.

3. After FORCE was installed, new pumps were also installed. Separate meters were installed on this new additional equipment. In the graph the consumption of the new pumps is deducted from the total consumption.

Wattage consumption with same flow (Consumption), 9.45%

1. The above graph shows the sum of watt consumption for each day before and after the FORCE installation. In order to compare data, the red circles (“consumption at the same flow”) were also analyzed.

2. A reduction in daily wattage consumption is important because it results in a lower electricity bill.

3. An overall reduction in total wattage consumption is evident at the same flow.

The operating temperature drops in both engines and other electrical equipment

1. Temperature drop measured with Flir camera in a pump engine.

2. Average temperature reduction from 121.2 F (Before) to 85.1 F (After) is 29.8%.